Centerless Grinding – 2 Day Master Seminar

Through- & In-feed Grinding – Theory & Live Demo / International locations

Industries:

Your takeaways

Modules

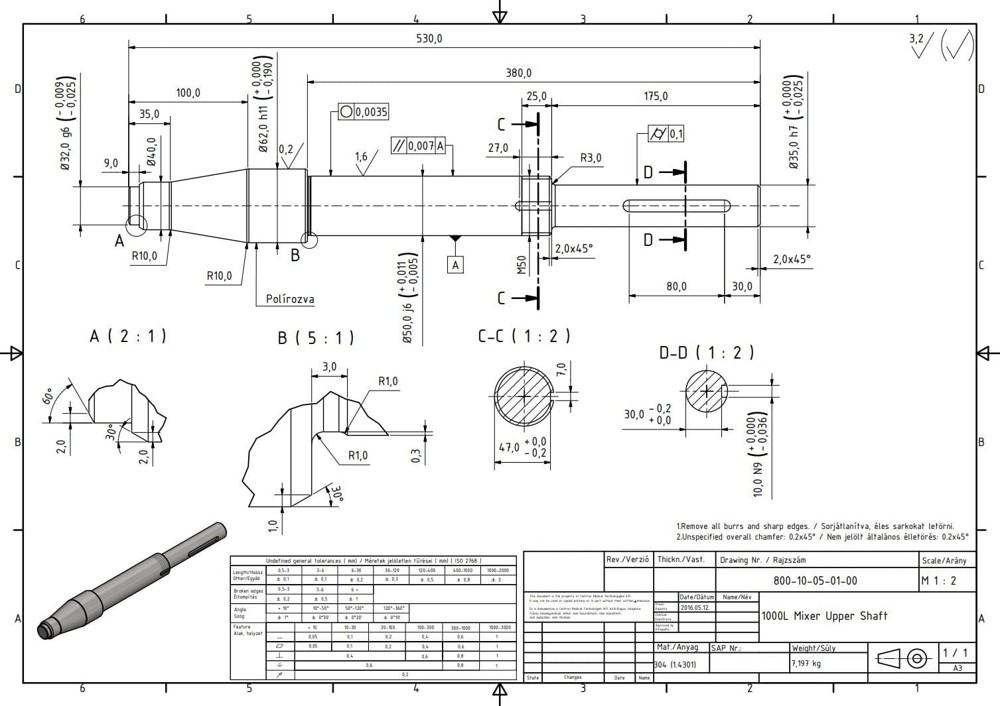

feasibility check & geometrical limits

In this module, you will learn which characteristics of a technical drawing you should pay attention to in order to check when a component can be ground centerless and when it cannot, which functional surfaces place which demands on the dressing process, and much more.

Takeaway: You will receive and understand a list of specifications for an efficient inquiry regarding centerless grinding.

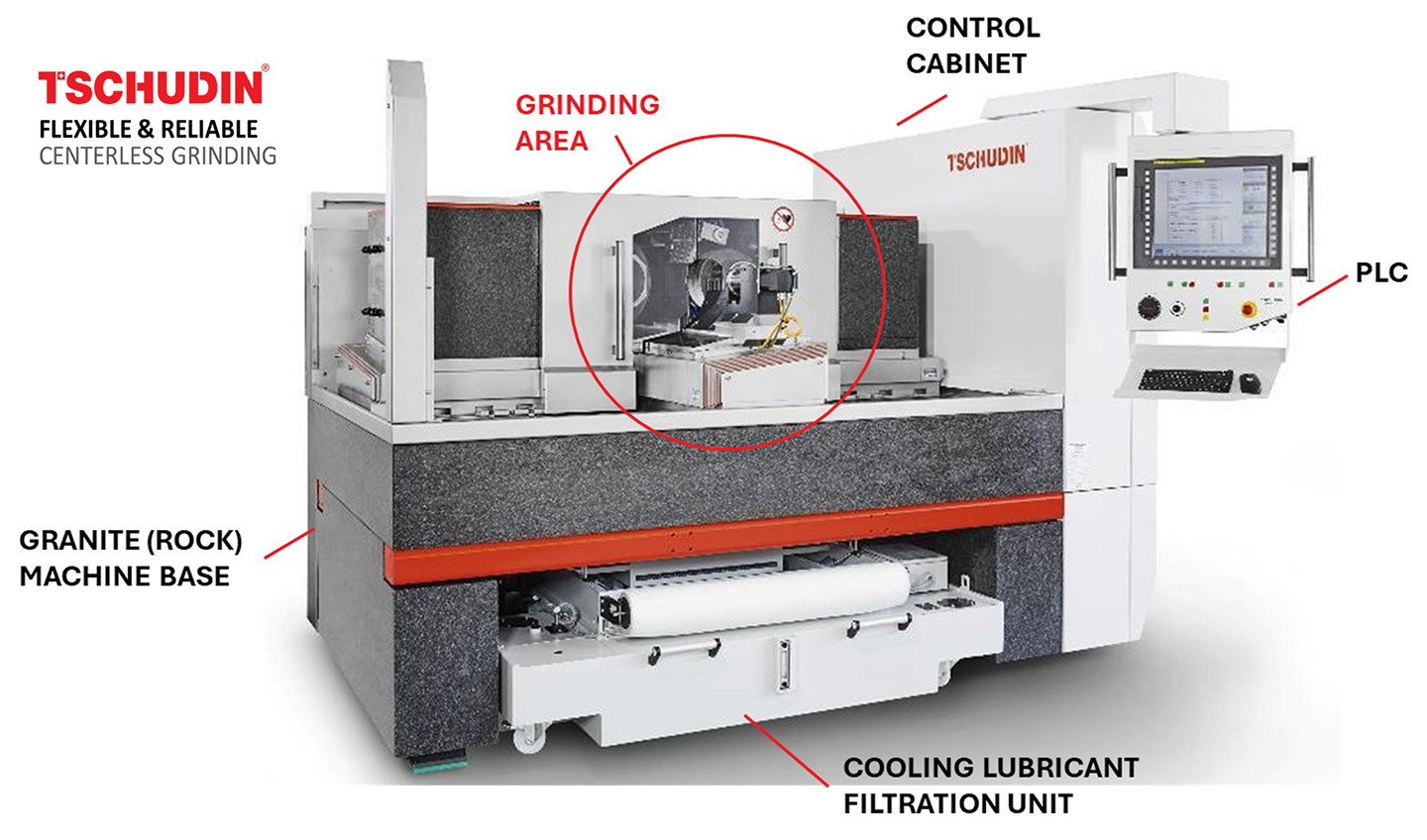

pro’s & con’s of machine components frequencies & how to control them

Learn about the components that make up a centerless grinding machine and the functions performed by each component. With all components, whether machine bed, spindle drives, or support rails, there are certain things to consider, such as vibrations and heat flow, to ensure that your process can be run economically and successfully.

Takeaway: Checklist

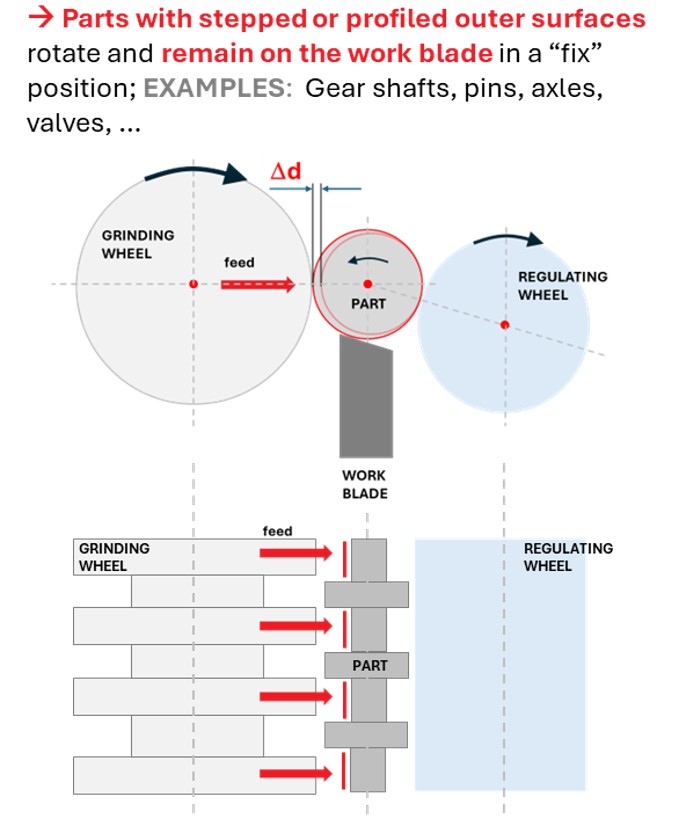

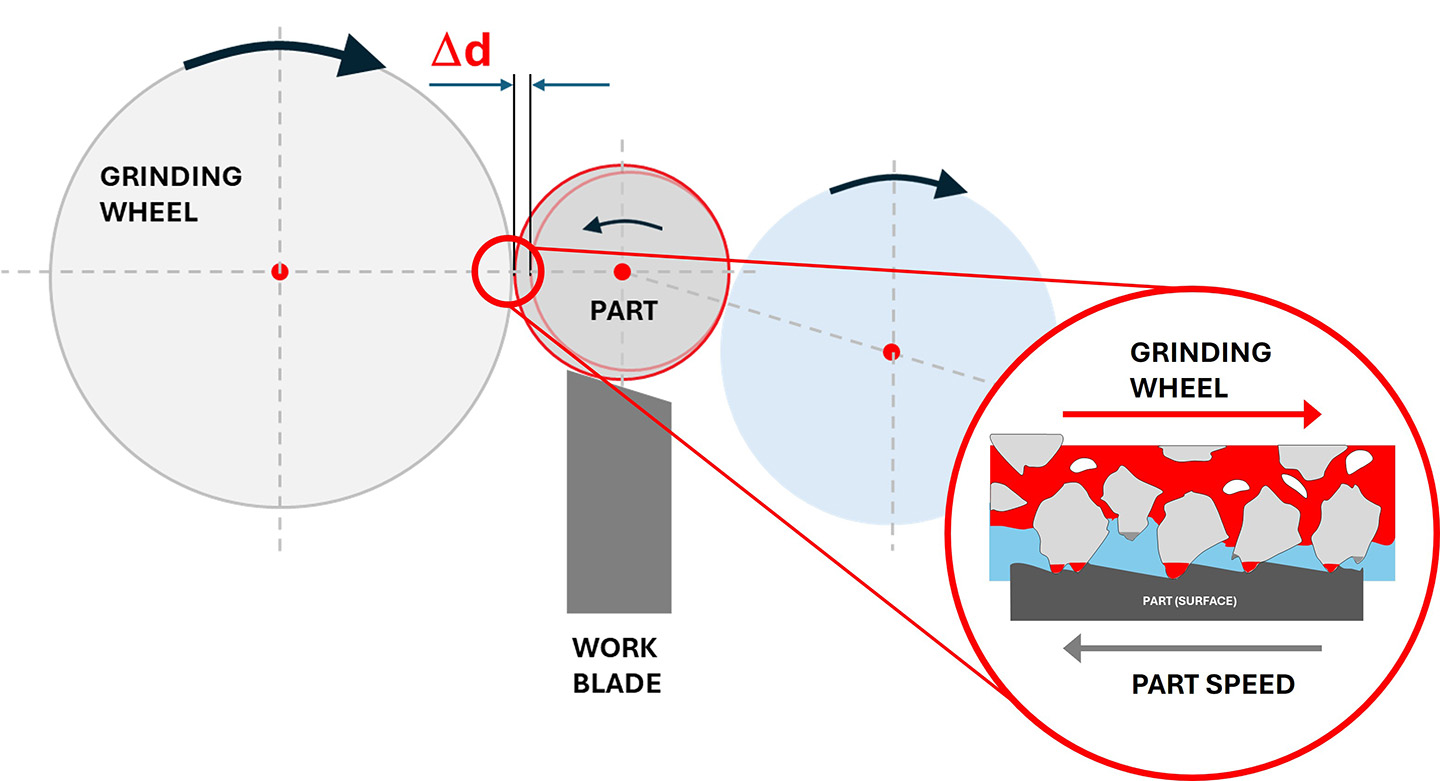

through-feed- & In-feed grinding

There are basically two different process variants. In this part of the seminar, you will learn when centerless through feed grinding can be used and for which component geometries only centerless in-feed grinding can be used.

- part / tool / blade changes

- geometry adjustments

- optimized dressing operations

How can you minimize setup times, and what do you need to pay particular attention to when designing the centerless grinding machine for your specific manufacturing task? How can you check the geometric settings of your machine using the simplest of means? This module provides you with the right answers to these questions.

Takeaway: Checklist

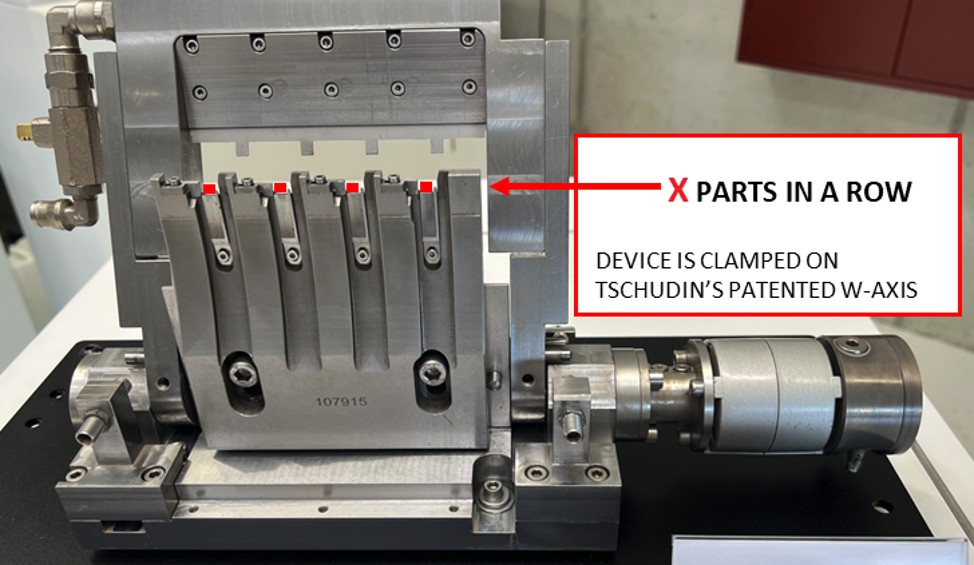

- part loader / feeder

- Robotics / …

In this part of your advanced training, you will learn about the automation solutions available for centerless grinding and what to look for when making your selection, such as gripper design, multi-stage manufacturing processes (in-feed), and component handling in the infeed and outfeed of the machine (through feed).

We will present automation solutions for both process variants using practical examples.

Takeaway: Checklist

- part quality

- machine & process diagnosis

- Intelligent work blade

The sixth module of our two-day master seminar on centerless grinding deals with the possibilities of integrated measurement technology for recording component quality, such as diameter accuracy, with automatic adjustment of the machine programming to achieve the lowest total cost of ownership.

We also explain which sensors are used for machine condition diagnosis and which ones provide valuable information for maximum overall equipment effectiveness (OEE).

Takeaway: Checklist

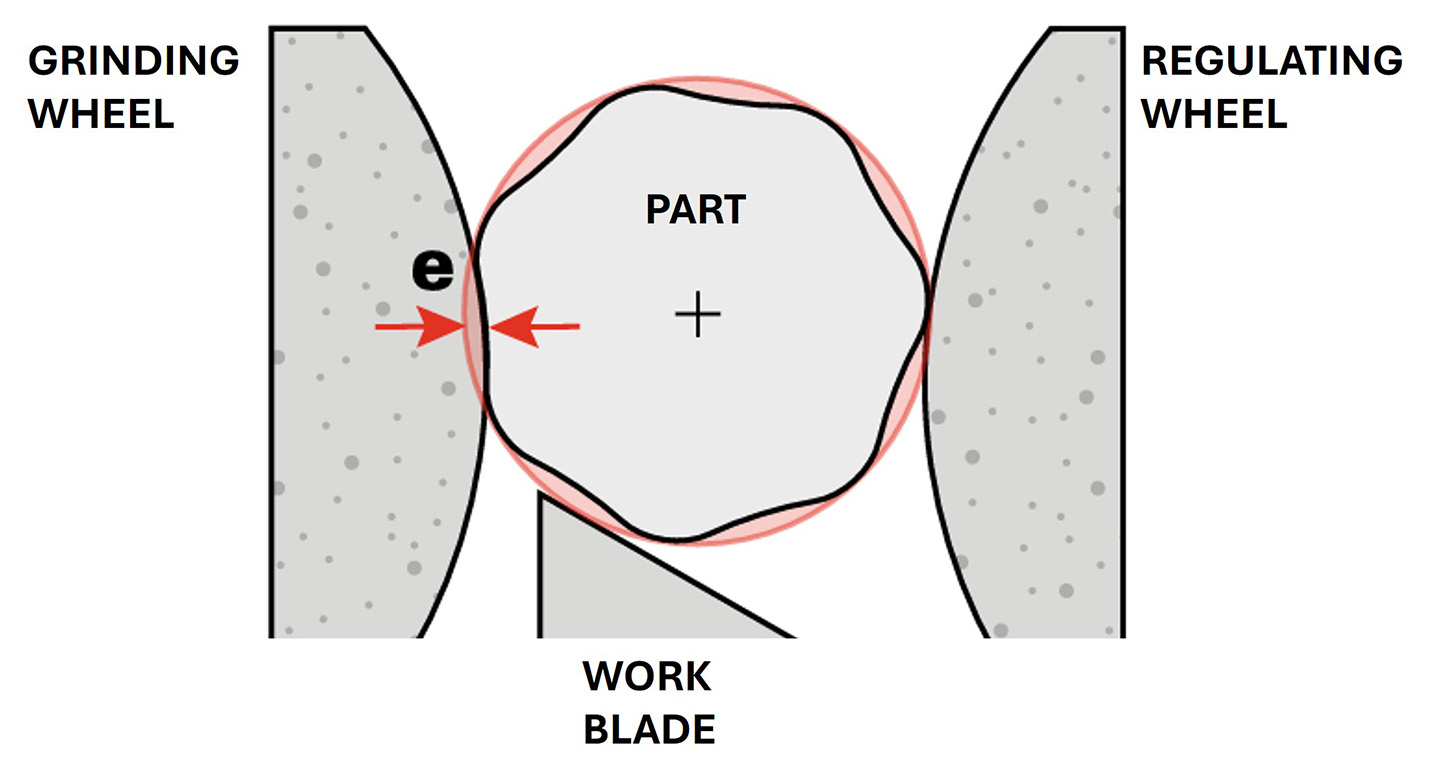

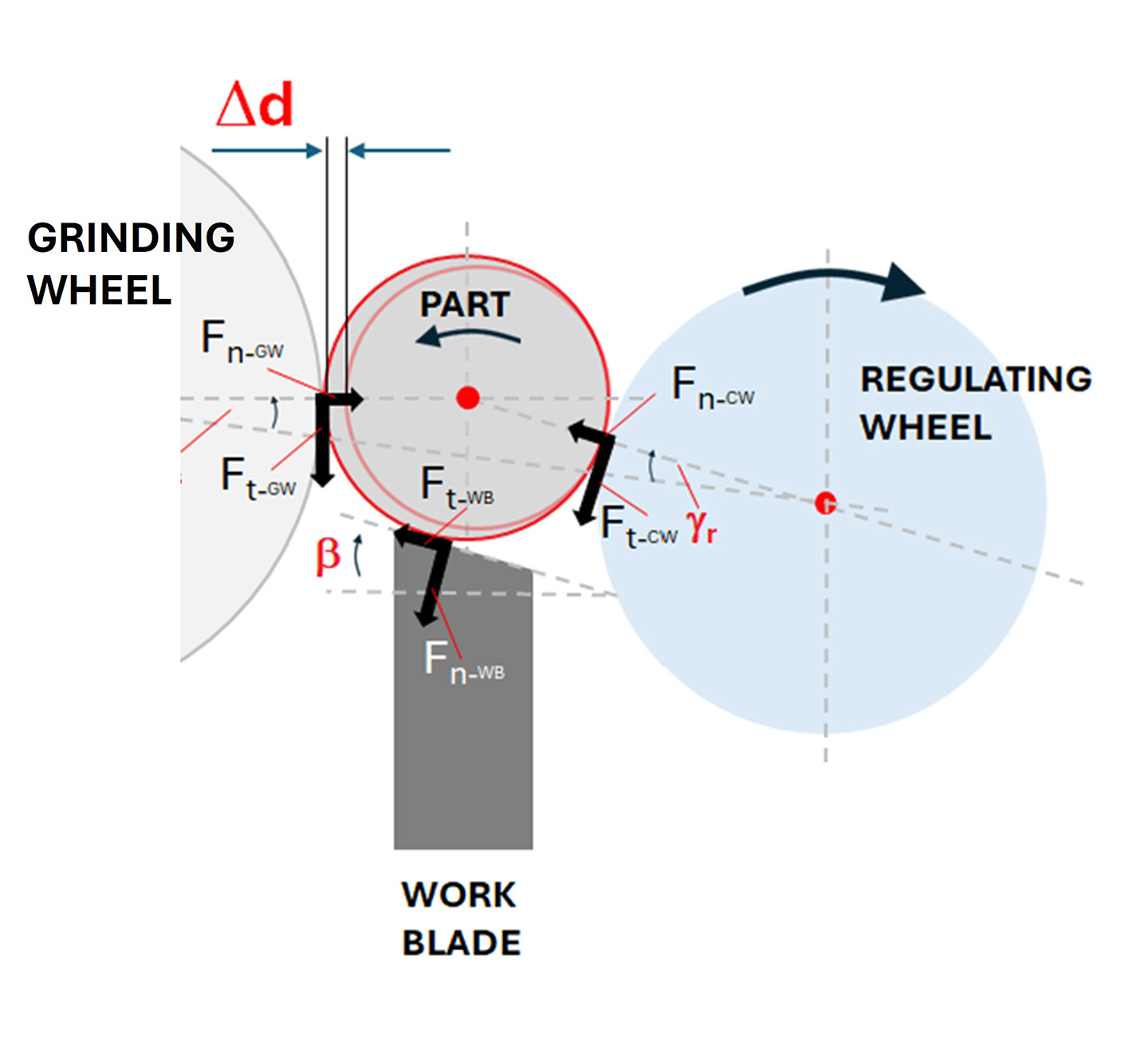

- 3 different rounding effects

- Avoiding mistakes

Roundness errors can have many different causes. In this module no. 7, we explain all the causes and possible solutions, such as geometric roundness effects, dynamic machine stability, and workpiece out-of-roundness of raw parts. We discuss with you what to look out for, how to correctly check and adjust the grinding gap geometry (machine settings), and what options you have to actively influence the avoidance of unwanted roundness errors.

Takeaway: Checklist / Guide for a successful trouble shooting

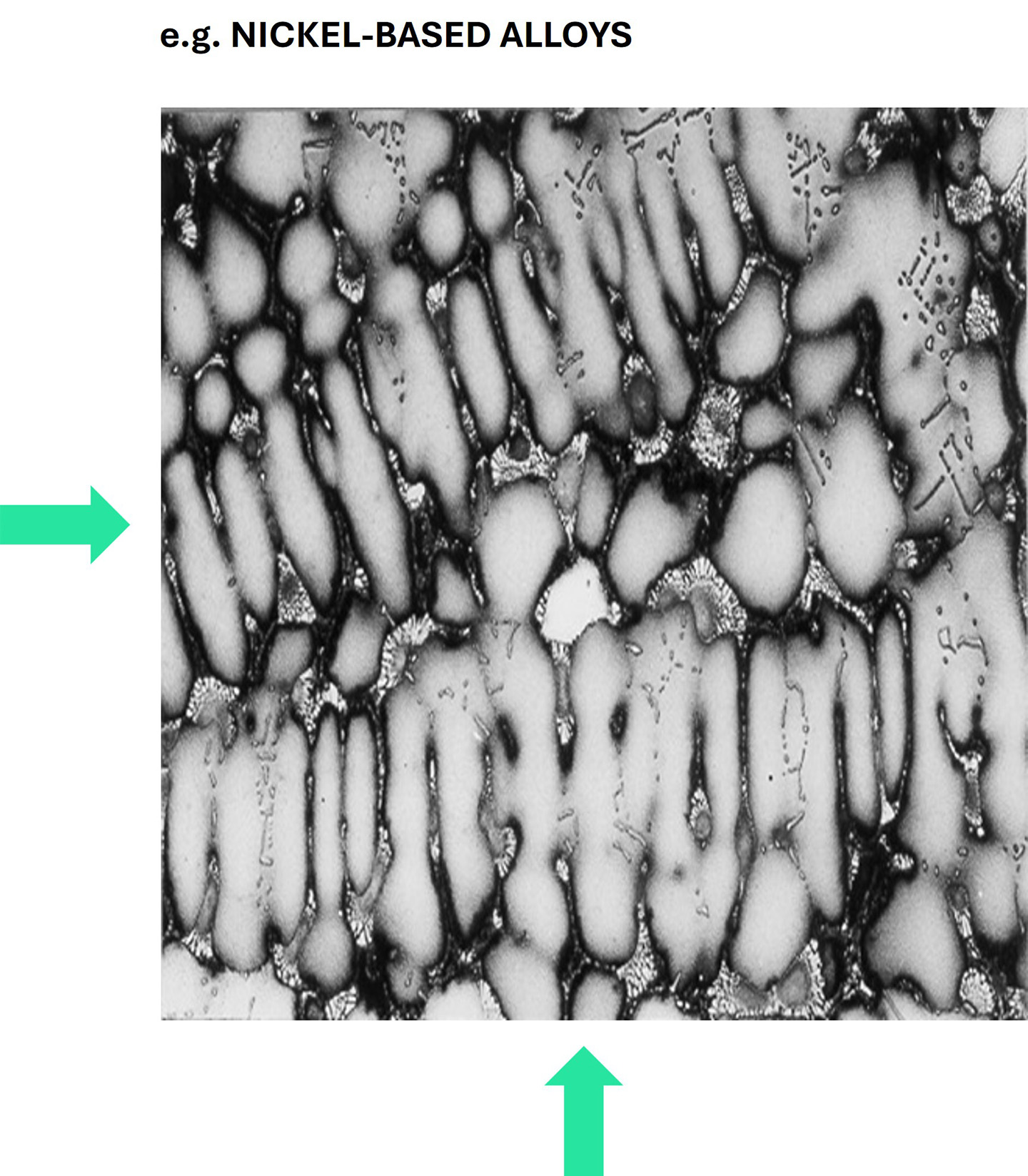

- all steel types

- cemented carbides

- ceramics

- nickel based alloys, titanium

Each material has its own properties that influence its grindability. We discuss clogging of grinding tools, chip formation mechanisms, dressability of grinding tools, tool porosity, grinding forces, heat generation in the grinding zone, heat dissipation options, and much more, so that your centerless grinding process can be designed to be as efficient and effective as possible right from the start.

Takeaway: Understanding materials and checklist of material-related failure possibilities

- supply technology

- filtration & fluid purity

- oil, synthetic, emulsion

In this part of the seminar, we will address questions relating to topics such as acquisition costs, installation costs, operating costs, maintenance costs, friction reduction properties, chip formation in grinding, slippages at the regulating wheel, and heat dissipation for neat oil and water-based emulsions.

Takeaway: Cooling lubricant checklist

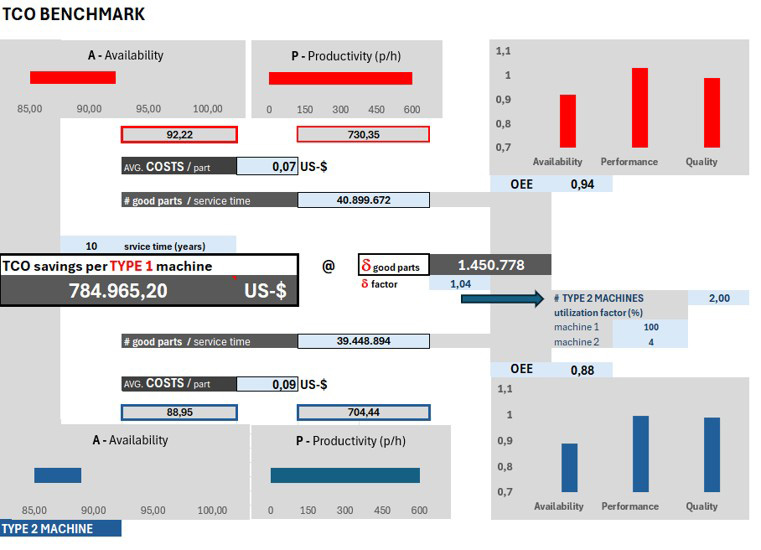

- Live Demo Software / Application Example

- TCO / Total Cost of Ownership

- OEE / Operational Effectiveness

How can you relate and benchmark technical advantages of a machine tool with your monetary benefits over the full machine service time and present them in a completely transparent way? It’s easy! With the help of the Tschudin TCO tool. We show you how much money you can earn with a Tschudin machine! Explore new opportunities with our Tschudin Centerless Grinding Solutions at highest OEE – Overall Equipment Effectiveness.

TCO: Total Cost of Ownership & OEE: Overall Equipment Effectiveness over the full total machine tool lifecycle we do consider:

Manufacturing costs / Set-up times / Availability / Productivity / Quality / Part costs / Materials / Operating resources … and much more

Takeaway: Understanding of TCO influence factors

- options for AI assisted grinding

- Humanoids as operators

- AR based services

This module aims to show you where the technological journey in centerless grinding is headed. AR-based maintenance, remote service deployment and its limitations, intelligent support rails, data management in centerless grinding technology, what to look out for when using AI tools (pros and cons). Examples from application technology (USA/Europe), humanoid robots as the operating personnel of tomorrow (illusion or reality?), potential for TCO reduction and OEE maximization through the use of automation and robot solutions.

Takeaway: Lots of good ideas to enhance your production efficiency

Event dates (f2f - presence / seminar)

Fees & Packages

Speaker

Dirk Friedrich, Dr.-Ing. MBA

Expert in centerless grinding, machine optimization, manufacturing (precision) technology, material behavior, cooling lubricants, filtration technologies. Extensive experience in metalworking 28+ years, more than 7500 machines optimized

Our Partners

Tschudin AG – fritzgoldberg represents Tschudin AG in USA, Mexico, Canada, Germany (North), Scandinavia.